AMANN – The company history

1854: The Bönnigheim sewing thread factory opens its doors

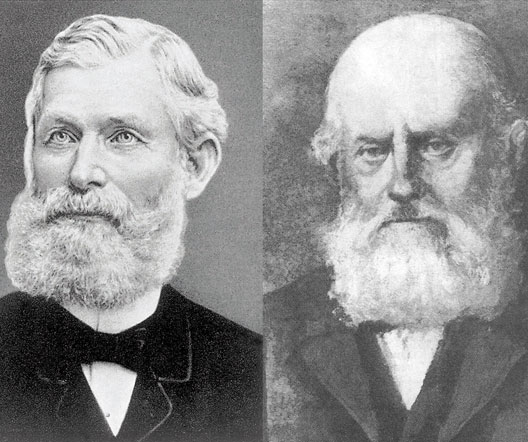

Bönnigheim, 1854: Alois Amann and Immanuel Böhringer founded the Amann & Böhringer company “for the purpose of manufacturing twined and dyed silks”.

Silk in the 19th century was a precious material and difficult to obtain. Professionally processing it into silk threads was considered a supreme discipline.

Amann and Böhringer were pioneers in Europe of an exacting art that had few imitators at the time.

1854 – 1880: Between sweat and growth – the founding years

In 1879, the young company celebrated its 25th anniversary. It had now become established as “the leading company among the German silk thread-makers”. But it had been a long journey. In the beginning, Amann & Böhringer employed 12 women thread-makers, two wheel movers, and several donkeys and oxen to power the machines. Despite this extremely laborious and strenuous work, the company soon started to flourish.

1880 – 1900: A name goes down in history

After Imanuel Böhringer left the company in 1882, Alois Amann brought in his two sons Emil and Alfred as partners, and renamed the company Amann & Söhne. Until his death in 1892, founder Alois Amann remained the sole owner.

1900 – 1920: A new factory for a new century

At the beginning of the 20th century, Amann & Söhne made a new start too: the old factory building was demolished in 1902 to make way for a new factory on the same site. The red-brick building still serves as the company’s headquarters today.

Changes were underway inside the building as well: Emil and Alfred Amann were jointly running the company, and realised early on that market demands were changing. In response, they began to produce artificial silk. In 1917, Emil Amann retired from the company.

1920 – 1940: New production methods

In 1919, in a characteristic and defining move, Amann & Söhne started to manufacture schappe silk. In 1923, production was expanded to include mercerised cotton. Both remain typical manufacturing methods in sewing thread production to this day.

1940 – 1954: Phoenix from the ashes – reconstruction after fateful years

Alfred Amann, the esteemed managing director and driving force behind the company, died in 1942 aged 78. His son-in-law Alfred Pielenz took over management of the company. Despite massive import and logistics problems, Pielenz succeeded in bringing the business and its production levels back to normal just a short time after the end of World War II.

1954: 100 years of AMANN

The company celebrated its centenary in 1954.

1955: Pioneering work in synthetic threads

As a trailblazer in a leading position, AMANN perfected the development and production of continuous filament synthetic sewing threads. The Serafil brand was born. To this day, its name represents unique quality.

1955 – 1968: Market launch of saba

A new era in synthetic sewing threads begins: thanks to intense research and development work, the 1950s and 1960s were a defining period that culminated with the launch of saba in 1968. With its characteristic and innovative three-cylinder construction, the age of innovative synthetic sewing threads had begun.

1968 – 1980: Rapid growth and inventive spirit

The successful development of Rasant began in 1974 with the first polyester/cotton core-spun thread of its kind.

The innovative spirit continued, as once again AMANN broke new ground in sewing thread technology. sabac is the brand name of the polyester/polyester core-spun thread that has become established in the market since 1980 as “the all-rounder among all sewing threads”.

1980 – 2000: Preparing for the new millennium

Success must continue – into the new millennium, too. AMANN set the course at the end of the 20th century by acquiring the long-established Augsburg company Ackermann-Göggingen AG in 1994, together with its state-of-the-art dyehouse. AMANN therefore gained additional expertise in embroidery threads.

In 1996, all logistics processes were professionalised with the inauguration of the fully automated industrial central warehouse at Erligheim, close to Bönnigheim. This confirmed AMANN’s status as one of the world’s biggest sewing thread manufacturers.

2000 – 2004: Internationalisation and technologisation

In 2001 and 2002, AMANN acquired the long-established British firm Donisthorpe, and the French sewing thread manufacturer Cousin Filterie.

techX Performance Threads, a new speciality range for technical textiles, was successfully launched a short time later, in 2002. It creates a whole new spectrum of possibilities for many different industries. New standards in underwear, sportswear and swimwear have been set since 2003 with the market launch of Sabaflex, an extremely elastic sewing thread.

2004 – 2013: Expansion to other countries

In 2006, a new production facility opened near the Romanian town of Brasov. Launched that same year, the new braided thread line Serabraid promises new dimensions in expressive design. AMANN continues to develop its expertise in the automotive field, and has increased its impact in the international sector with the acquisition of long-established British firm Oxley Thread Ltd., one of the best-known sewing thread manufacturers in Europe.

Expansion in the Asian market: with the opening in 2009 of its first production site in Asia, in the Chinese city of Yancheng, AMANN has improved product availability and customer service in the Asian region.

In 2013, AMANN expanded into Bangladesh. A new state-of-the-art production facility was inaugurated near the capital city, Dhaka.

2013-2018: Focus on innovation

In 2014, AMANN launches Sabasoft, an extremely soft sewing thread that combines performance and softness for the first time.

To develop innovative solutions and concepts for sewing threads, embroidery threads and smart yarns is the goal of the AMANN Innovation Lab, which opened in 2017. This textile development hotbed at the Augsburg site carries out intensive research and development activities.

AMANN's Road to Zero - in 2018, the new water-repellent WRe finish is launched. It is even more environmentally friendly than the conventional WR finish, as it does not contain any PFC.

Present: AMANN, the sustainable global player

In the Vietnamese coastal city Tam Ky AMANN opens its third production site on Asian ground in 2019. The new plant will produce 2,300 tons of sewing thread per year.

In 2019, AMANN also joins the UN Global Compact and publishes its first Sustainability Report.

In the beginning of 2020, AMANN launches its new sustainable product range. It consists of the RECYCLED line with products that are made from 100% recycled PET bottles, and the LIFECYCLE line. The new product Lifecycle Polyamide is even the first sewing thread to receive the Cradle to Cradle® certification at Gold level for technical cycles.

In 2022, the long-standing AMANN CEO Bodo Bölzle retires. The AMANN management will henceforth consist of four managing directors and will be expanded to include the new position of a Chief Sustainability and Innovation Officer (CSIO).

In addition, the construction of the first Indian AMANN production facility in the southern Indian city of Ranipet, Tamil Nadu, begins in 2022.