High-performance sewing threads for technical textiles

Application

Technical textiles must perform reliably under the most demanding conditions – whether in protective clothing, outdoor gear, or industrial applications. Our specialised sewing threads offer exceptional tear resistance, resistance to extreme temperatures and chemical exposure, as well as UV stability. They ensure seams remain secure and durable even under heavy stress. From medical protective wear to tents, awnings, and safety-critical textile products – our high-tech threads help maintain the quality and reliability your applications require.

Medical protective clothing

In the medical field, safety, hygiene, and wearing comfort are crucial – right down to the smallest detail. Our specialised sewing threads for medical protective clothing are highly tear-resistant, sterilisation-proof, and resistant to disinfectants and frequent washing. They ensure reliable seams for surgical gowns, protective coats, masks, and other medical textiles that must meet the strictest hygiene and performance standards. Our high-performance threads help combine protection and comfort seamlessly in healthcare environments.

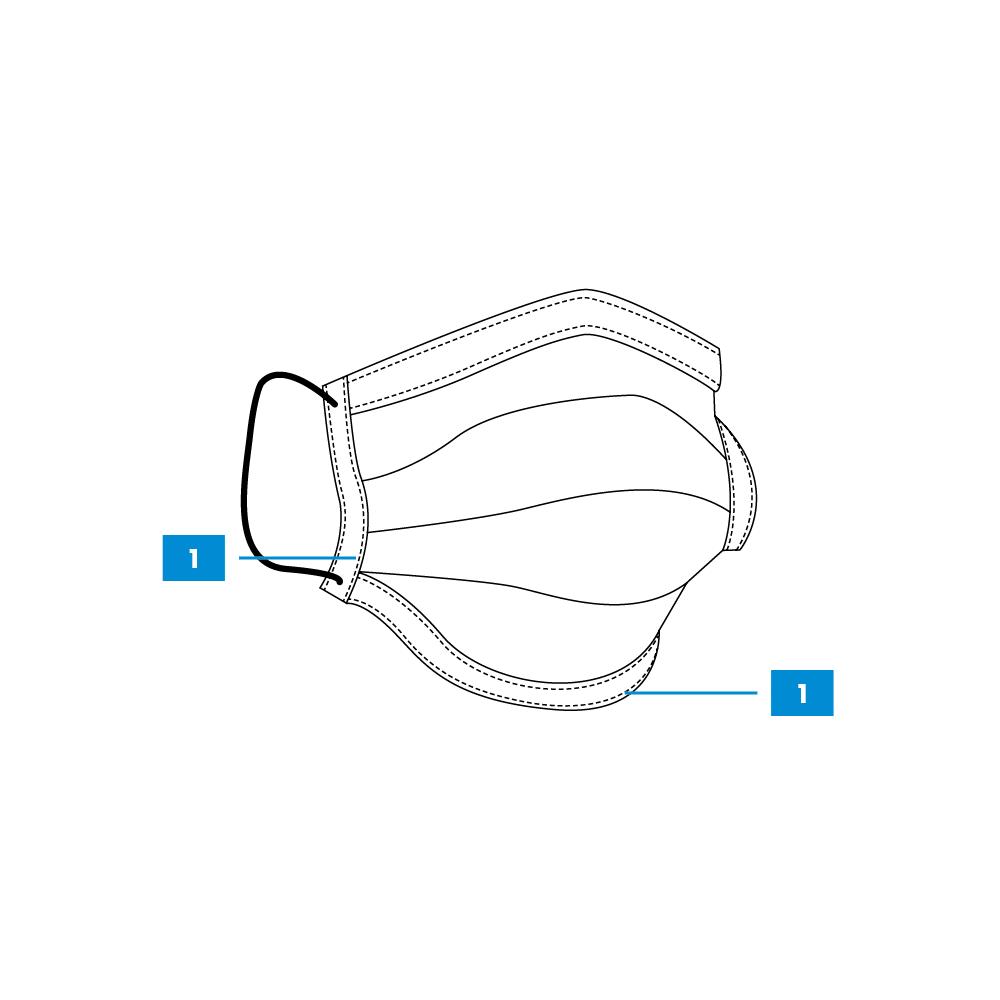

Surgical masks

AMANN sewing thread recommendation for surgical masks

Our sewing thread recommendation for processing surgical masks is Saba 120.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. no | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing and topstitch seams | 301 lockstitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

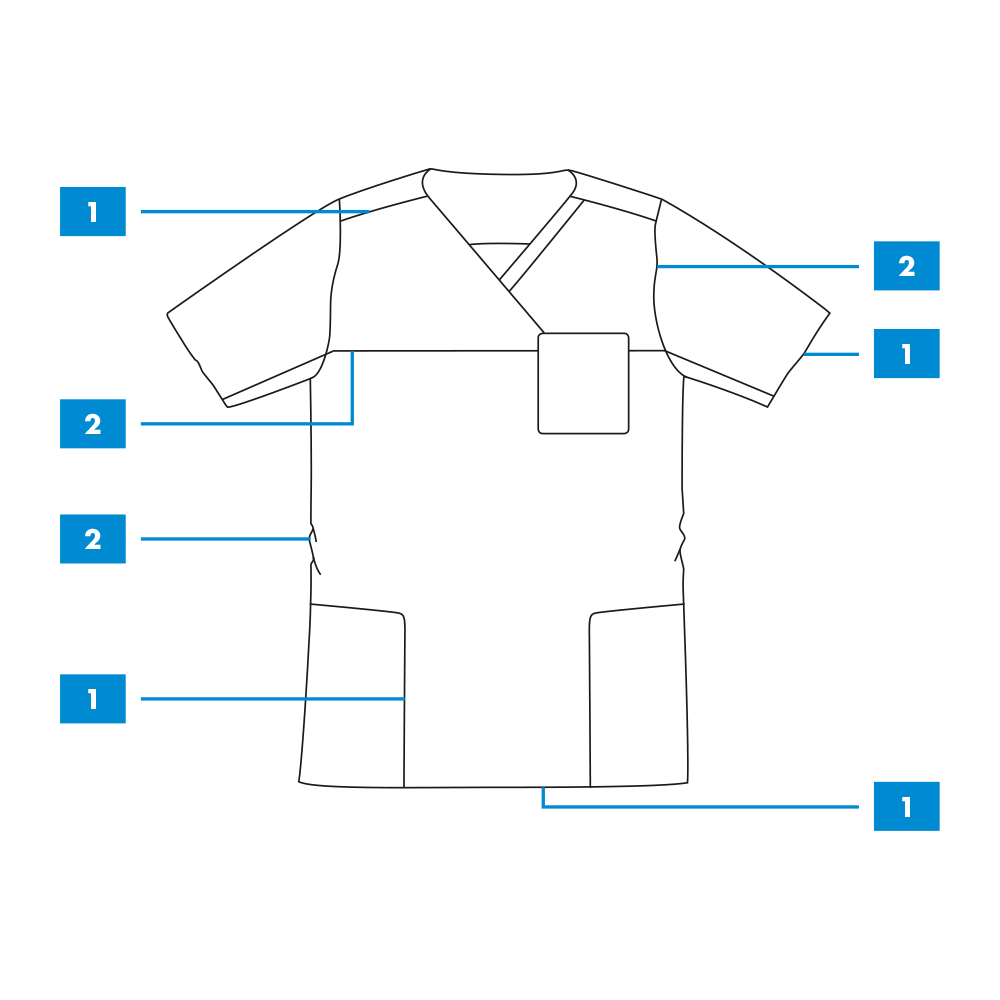

Casaque

AMANN sewing thread recommendation for casaque

As an universal sewing thread for casaque we recommend Saba 120.

Depending on the fabric and the sewing conditions, such as the stitch density and stitch type, it might be worthwhile selecting other qualities from the AMANN range:

- for emblem embroidery Isacord and Serafil fine

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing and topstitch seams | 301 lockstitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

| 2 | Closing seams | 514 4-thread overlock stitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

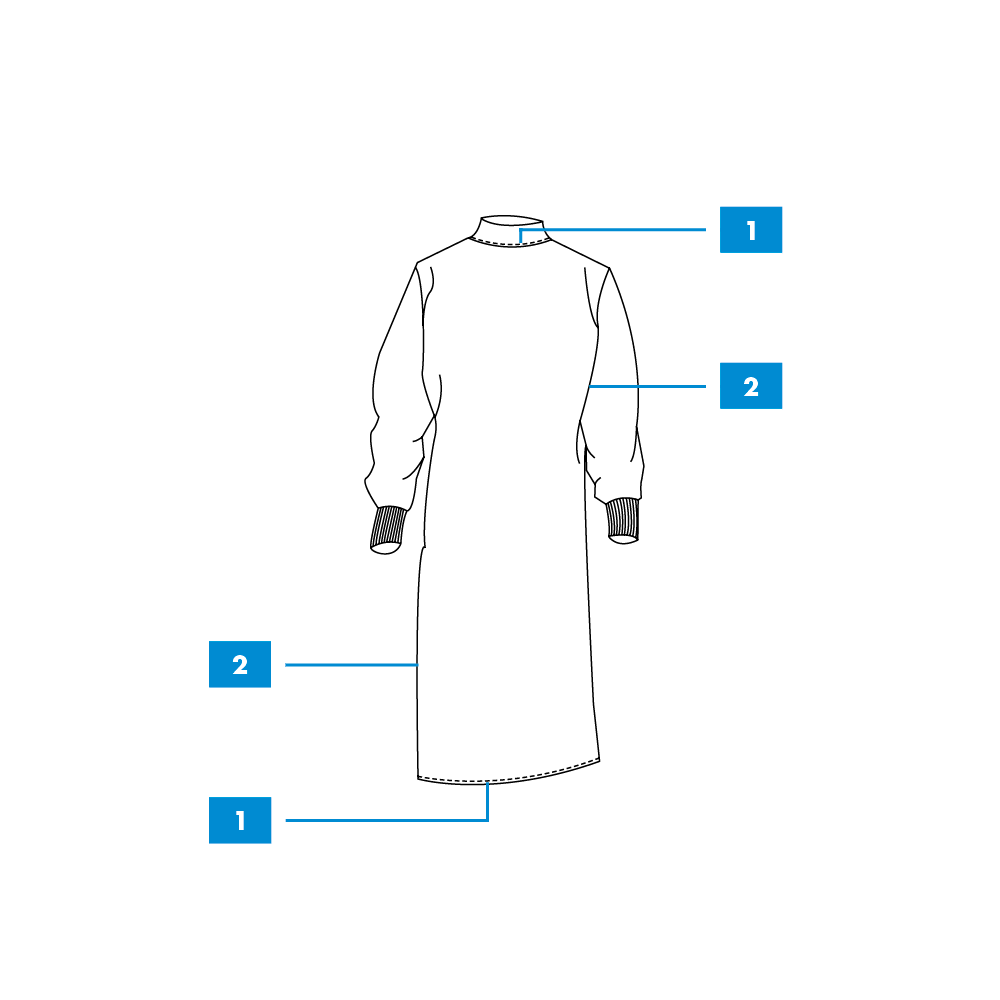

Surgical gown

AMANN sewing thread recommendation for surgical gowns

Our sewing thread recommendation for processing surgical gowns is Saba 120.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing and topstitch seams | 301 lockstitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

| 2 | Closing seams | 514 4-thread overlock stitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

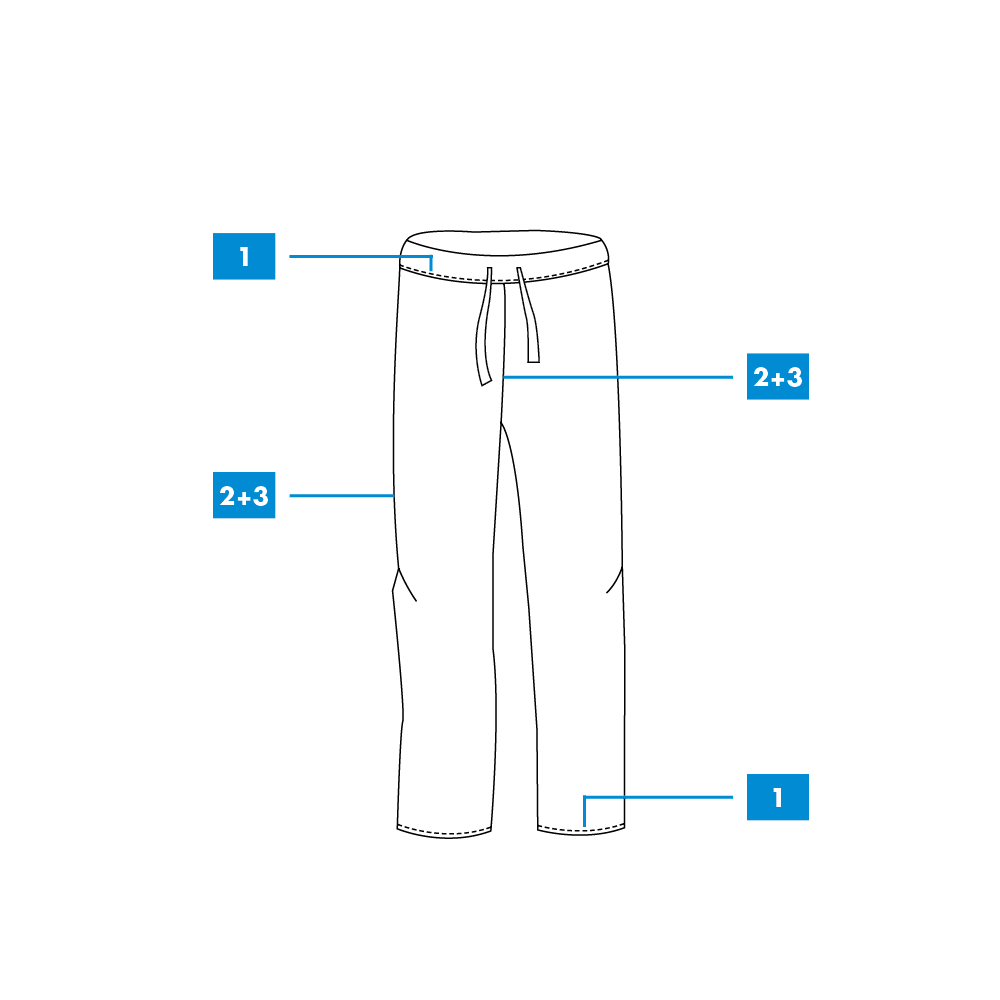

Surgical pants

AMANN sewing thread recommendation for protective clothing

Our sewing thread recommendation for processing surgical pants is Saba 120.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing and topstitch seams | 301 lockstitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

| 2 | Closing seams | 401 double chainstitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

| 3 | Serging seams | 504 3-thread overlock stitch | Saba | 120 | 24 | Saba | 120 | 24 | 65 | 9 | |||||||||||

Protective clothing

Protective clothing must perform reliably in extreme conditions – whether in industry, skilled trades, or emergency services. Our specialised sewing threads are exceptionally tear-resistant, heat- and flame-resistant, chemical-resistant, and built to withstand the toughest mechanical stress. They ensure secure, long-lasting seams in workwear, firefighting gear, rescue uniforms, and other safety-critical textiles. With our high-performance threads, you can create protective garments that meet the highest safety standards while delivering maximum protection.

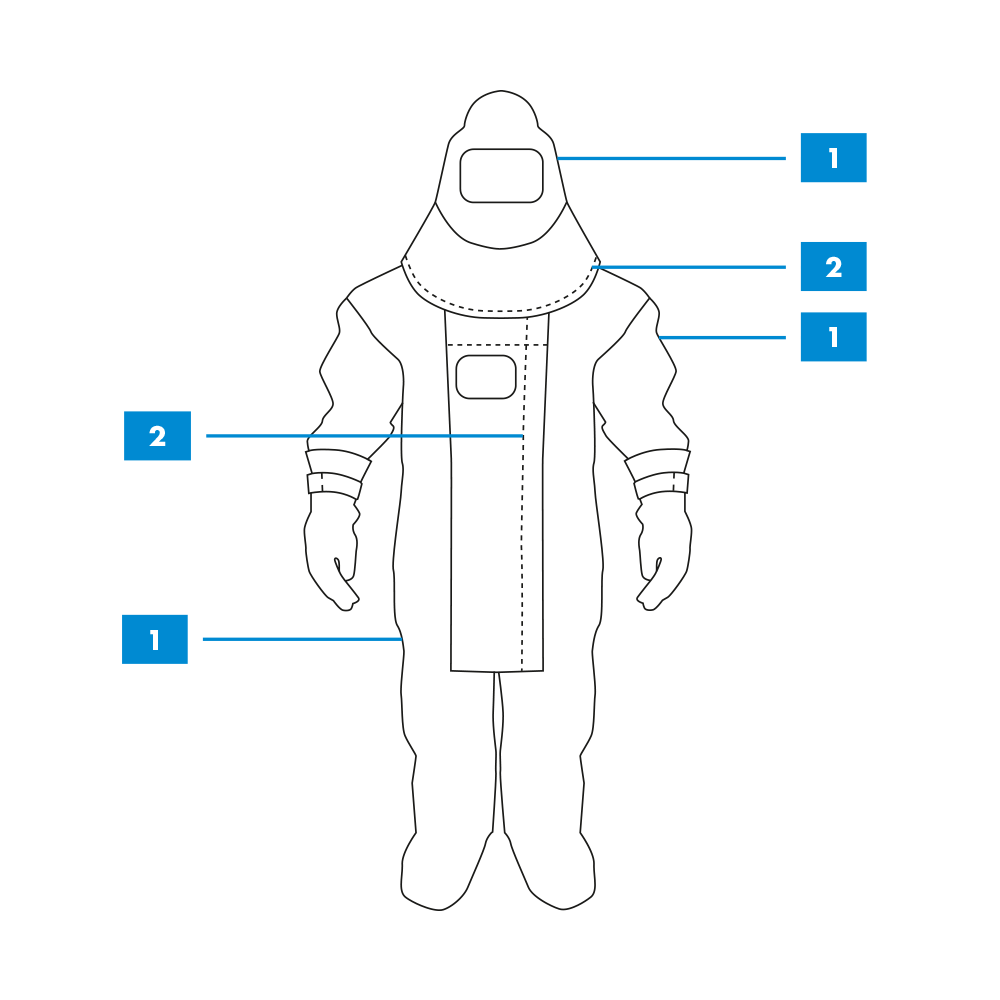

Protective clothing

AMANN sewing thread recommendation for protective clothing

Our sewing thread recommendation for processing protective clothing is K-tech.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing seams | 301 lockstitch | K-tech | 50 | 60 | K-tech | 50 | 60 | 110 | 18 | |||||||||||

| 2 | Topstitch seam | 301 lockstitch | K-tech | 35 | 80 | K-tech | 35 | 80 | 120 | 19 | |||||||||||

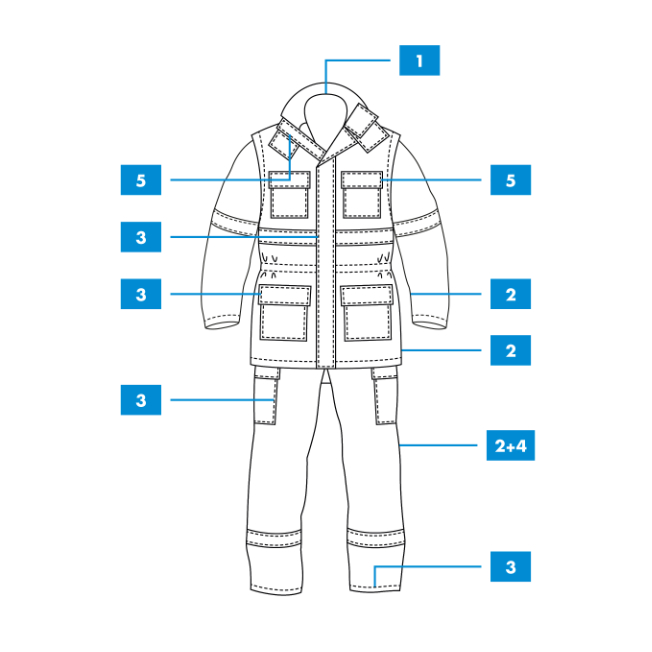

Firefighter uniform

AMANN sewing thread recommendation for firefighter uniforms

Our general sewing thread recommendation for processing firefighter uniforms is N-tech. For sewing seams on firefighter uniforms, we recommend using N-tech CS.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing and topstitch seams | 301 lockstitch | N-tech | 70 | 40 | N-tech | 70 | 40 | 80 | 12 | |||||||||||

| 2 | Closing seams | 401 double chainstitch | N-tech | 70 | 40 | N-tech | 70 | 40 | 80 | 12 | |||||||||||

| 3 | Topstitch seams | 301 lockstitch | N-tech | 40 | 75 | N-tech | 70 | 40 | 100 | 16 | |||||||||||

| 4 | Serging seams | 504 3-thread overlock stitch | N-tech CS | 120 | 25 | N-tech CS | 120 | 25 | 70 | 10 | |||||||||||

| 5 | Bar tack | 304 lockstitch | N-tech | 70 | 40 | N-tech | 70 | 40 | 80 | 12 | |||||||||||

Outdoor textiles

Outdoor textiles are exposed to the harshest conditions – from intense sunlight and heavy rain to strong winds and temperature fluctuations. Our specialised sewing threads are UV- and weather-resistant, tearproof, and abrasion-resistant, ensuring strong and durable seams even in the toughest environments. Whether for awnings, sun sails, tents, or outdoor cushions – our high-performance threads deliver maximum durability and consistently perfect results. Ideal for outdoor textiles that combine functionality, aesthetics, and long-lasting performance.

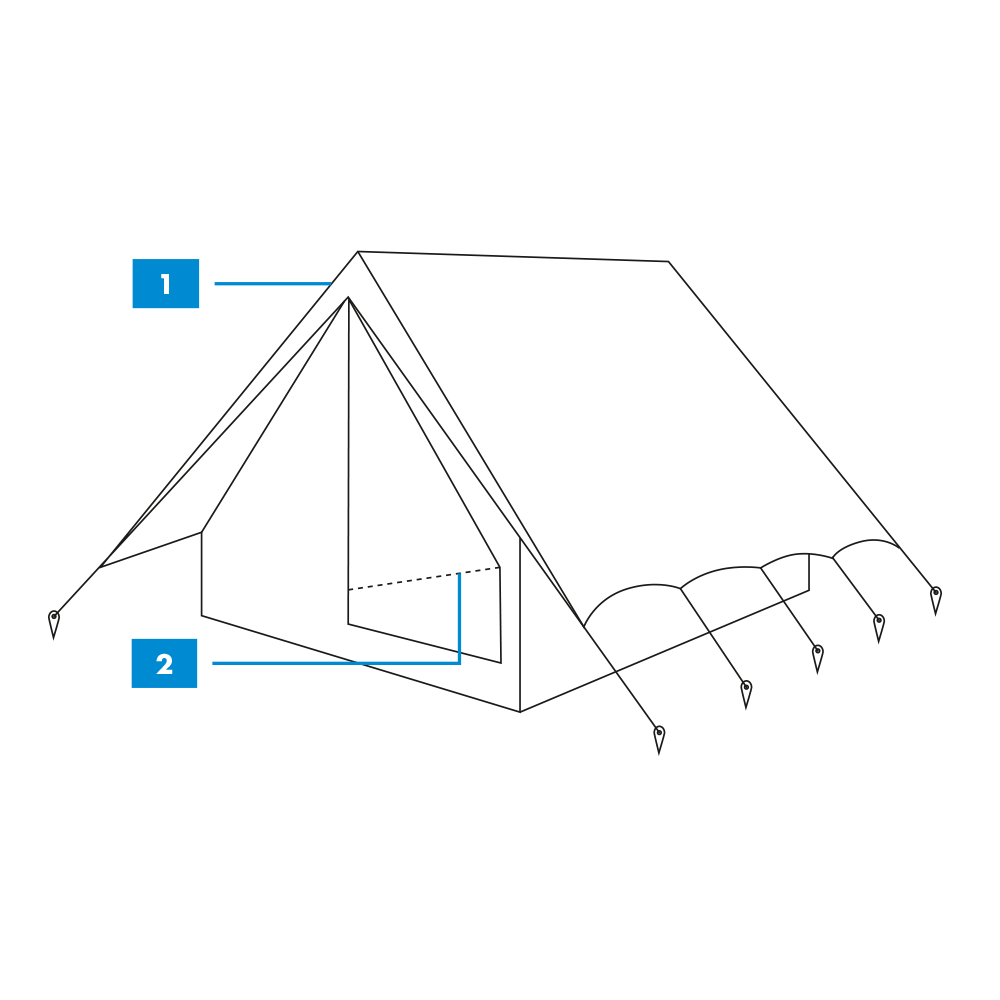

Tents

AMANN sewing thread recommendation for tents

Our sewing thread recommendation for processing tents is Outdoor-Pro.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Closing and topstitch seam | 301 lockstitch | Outdoor-Pro 40 | 40 | 70 | Outdoor-Pro 40 | 40 | 70 | 100 | 16 | |||||||||||

| 2 | Topstitch seam | 301 lockstitch | Outdoor-Pro 40 | 40 | 70 | Outdoor-Pro 40 | 40 | 70 | 100 | 16 | |||||||||||

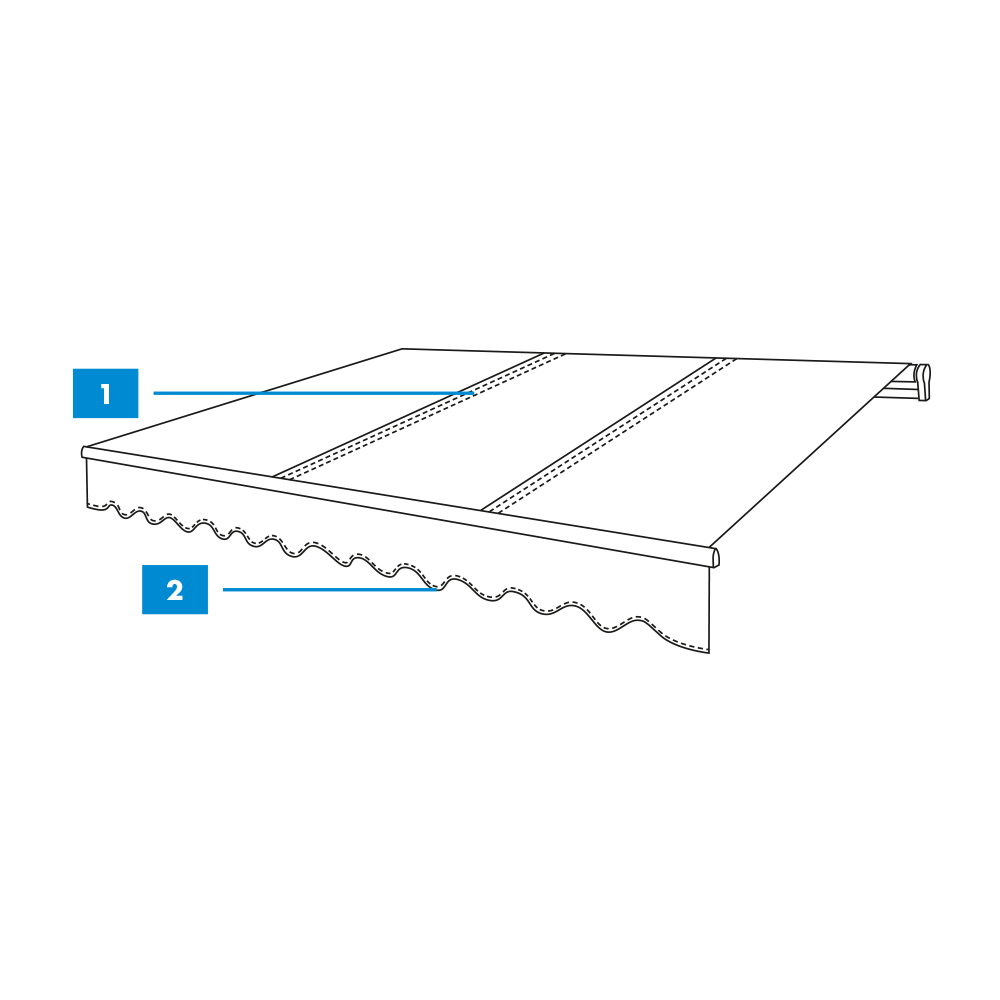

awnings

AMANN sewing thread recommendation for awnings

Our sewing thread recommendation for processing awnings is Outdoor-Pro.

| seam no. | seam type | stitch type | needle thread | bobbin or looper thread | needle size min. Nm | needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| article | ticket no. | tex no. | article | ticket no. | tex no. | ||||||||||||||||

| 1 | closing and topstitch seam | 301 lockstitch | Outdoor-Pro 40 | 40 | 70 | Outdoor-Pro 40 | 40 | 70 | 100 | 16 | |||||||||||

| 2 | topstitch seam | 301 lockstitch | Outdoor-Pro 40 | 40 | 70 | Outdoor-Pro 40 | 40 | 70 | 100 | 16 | |||||||||||

Tarpaulins

AMANN sewing thread recommendation for tarpaulins

Our sewing thread recommendation for processing tarpaulins is Outdoor-Pro.

| seam no. | seam type | stitch type | needle thread | bobbin or looper thread | needle size min. Nm | needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| article | ticket no. | tex no. | article | ticket no. | tex no. | ||||||||||||||||

| 1 | Closing seams | 301 lockstitch | Outdoor-Pro | 40 | 70 | Outdoor-Pro | 40 | 70 | 100 | 16 | |||||||||||

| 2 | Decorative seams | 301 lockstitch | Outdoor-Pro | 20 | 135 | Outdoor-Pro | 40 | 70 | 130 | 21 | |||||||||||

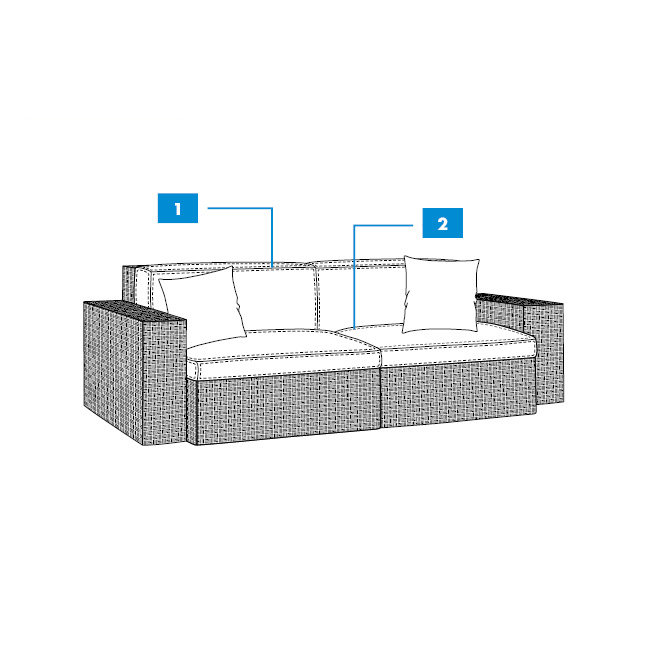

Outdoor furniture

AMANN sewing thread recommendation for outdoor furniture

Our sewing thread recommendation for processing outdoor furniture is Outdoor-Pro.

| seam no. | seam type | stitch type | needle thread | bobbin or looper thread | needle size min. Nm | needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| article | ticket no. | tex no. | article | ticket no. | tex no. | ||||||||||||||||

| 1 | Closing seams | 301 lockstitch | Outdoor-Pro | 40 | 70 | Outdoor-Pro | 40 | 70 | 100 | 16 | |||||||||||

| 2 | Decorative seams | 301 lockstitch | Outdoor-Pro | 20 | 135 | Outdoor-Pro | 40 | 70 | 110 | 18 | |||||||||||

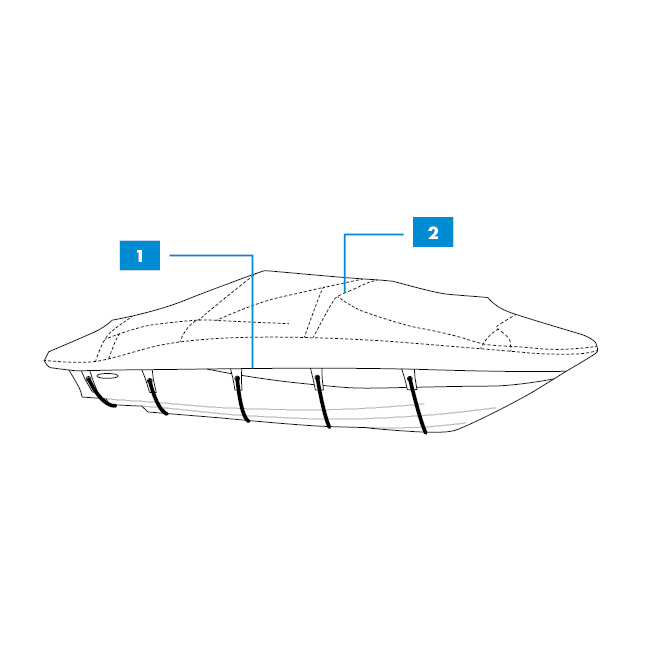

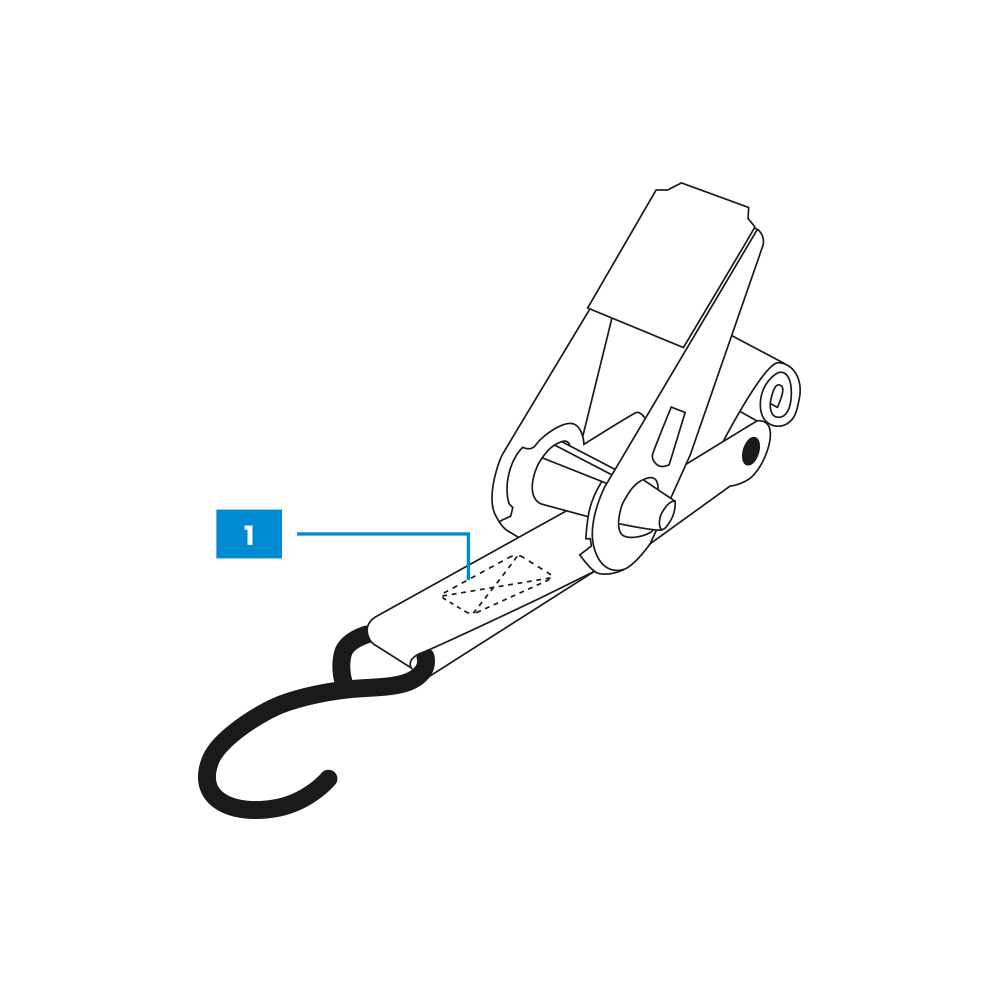

Lifting and restraint systems

Lifting and restraint systems must withstand extreme loads while ensuring maximum safety – whether in industrial environments, transport, or other safety-critical applications. Our specialised sewing threads provide outstanding tear strength, abrasion and weather resistance, and high tolerance to chemical exposure. They ensure strong, durable seams that hold reliably even under intense tension. Ideal for systems that demand uncompromising safety, durability, and long-term performance.

Hoisting slings and tethers

AMANN sewing thread recommendation for hoisting slings and tethers

Our sewing thread recommendation for processing hoisting slings and tethers is Xtreme-tech with Dyneema®. Serabond, Gore® Tenara® and Strongbond can be used as an alternative.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Topstich seams | 301 lockstitch | Xtreme-tech | 20 | 150 | Xtreme-tech | 20 | 150 | 160 | 23 | |||||||||||

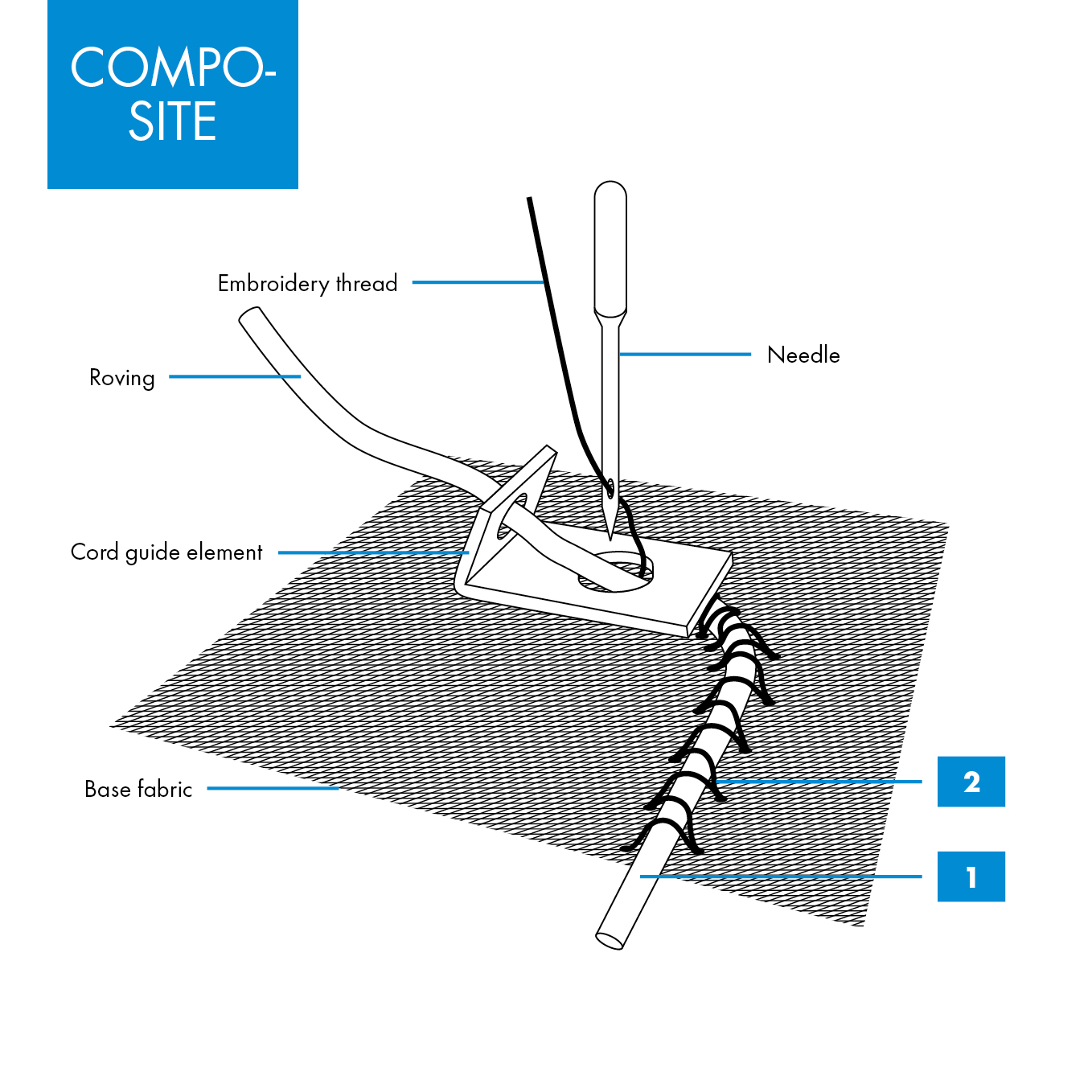

Composites

Composites represent top-tier performance in high-tech applications, from aerospace and automotive engineering to sports equipment and industrial products. Our specialised sewing threads and multifilament yarns are perfectly suited for processing composite materials. They offer exceptional heat resistance, chemical durability, and outstanding tensile strength for maximum stability and precision. Whether for preform structures, stitched reinforcements, or 3D textile composites – our high-performance threads enable reliable, robust, and long-lasting composite solutions for the most demanding applications.

Composites

AMANN sewing thread recommendation for composites

Our sewing thread recommendation for processing composites in the TFP embroidery process of thermoplastic components is Serafil Comphil.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Placed Roving | - | - | - | - | - | - | - | - | - | |||||||||||

| 2 | Fixing seam | 304 lockstitch zigzag | Serafil Comphil | 180 (120/2) | 16 | Serafil Comphil | 180 (120/2) | 16 | 65 | 9 | |||||||||||

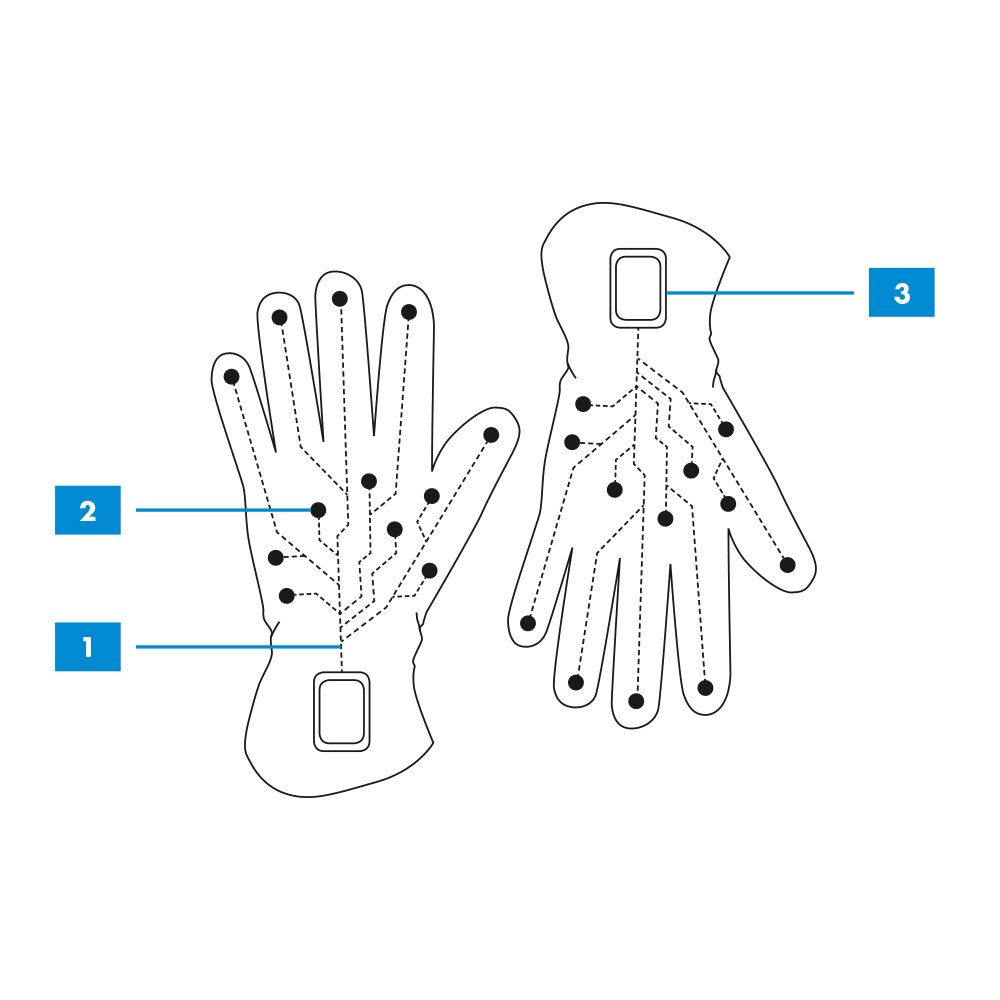

Conductive textiles

Conductive textiles combine flexibility with cutting-edge technology, unlocking new possibilities in areas such as wearables, sensors, and smart textiles. Our specialised conductive sewing and embroidery threads enable the seamless integration of electrical functions directly into textile structures. They offer excellent conductivity, high flexibility, and reliable performance – even in demanding applications. Whether for functional protective clothing, medical textiles, or interactive fashion, our high-performance threads

Conductive textiles

AMANN sewing thread recommendation for conductive textiles

Our sewing thread recommendation for processing conductive textiles is Silver-tech.

| Seam no. | Seam type | Stitch type | Needle thread | Bobbin or looper thread | Needle size min. Nm | Needle size min. No | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Article | Ticket no. | Tex no. | Article | Ticket no. | Tex no. | ||||||||||||||||

| 1 | Embroidered conductor | 301 lockstitch | Silver-tech | 120 | 28 | Silver-tech | 120 | 28 | 75 | 11 | |||||||||||

| 2 | Embroidered sensor point | 301 lockstitch | Silver-tech | 120 | 28 | Silver-tech | 120 | 28 | 75 | 11 | |||||||||||

| 3 | Power connector | 301 lockstitch | - | - | - | - | - | - | - | - | |||||||||||

Filters

Filter textiles play a vital role in industry, healthcare, and environmental technology – meeting the highest demands for particle filtration, air and liquid permeability, and chemical resistance. Our specialised sewing threads deliver exceptionally dense, durable, and resilient seams that perform reliably even under the most challenging conditions. Whether for air and liquid filters, dust collectors, or industrial filtration systems – our high-performance threads ensure maximum efficiency, stability, and durability for high-quality filter solutions.

Our sewing thread recommendation for processing filters is PP-tech.

D-tech and Zyex® can be used as alternatives.